Cellyx™

Cellyx™ offers high-performance acoustic foam panels designed for soundproofing and clarity in modern spaces. Made from low VOC and fire retardant acoustic foam, our panels feature high NRC ratings and advanced melamine foam properties for effective sound absorption. Ideal for acoustic ceilings, studios, and sustainable interiors, Cellyx™ combines the science of soundproofing with eco-conscious design.

Products

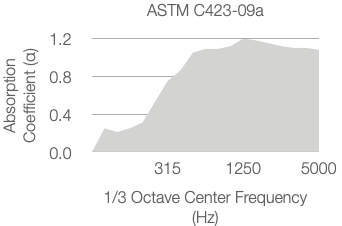

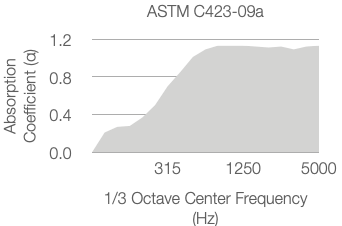

Cylinder 100

Cellyx™ Cylinder 100 baffles feature a 100mm diameter design in melamine foam, absorbing sound and reducing reverberation in open spaces.

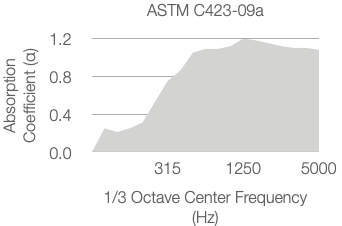

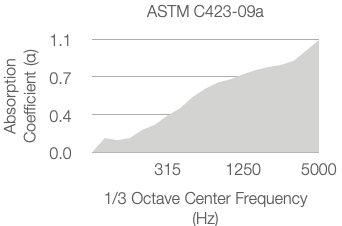

Cylinder 150

Cellyx™ Cylinder 150 baffles feature a 100mm diameter design in melamine foam, absorbing sound and reducing reverberation in open spaces.

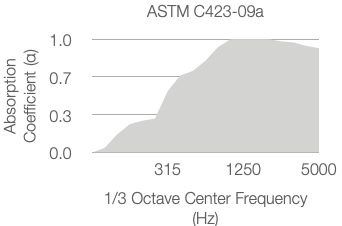

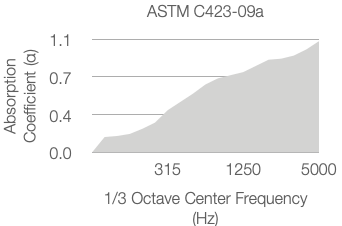

Cylinder 300

Cellyx™ Cylinder 300 baffles feature a 100mm diameter design in melamine foam, absorbing sound and reducing reverberation in open spaces.

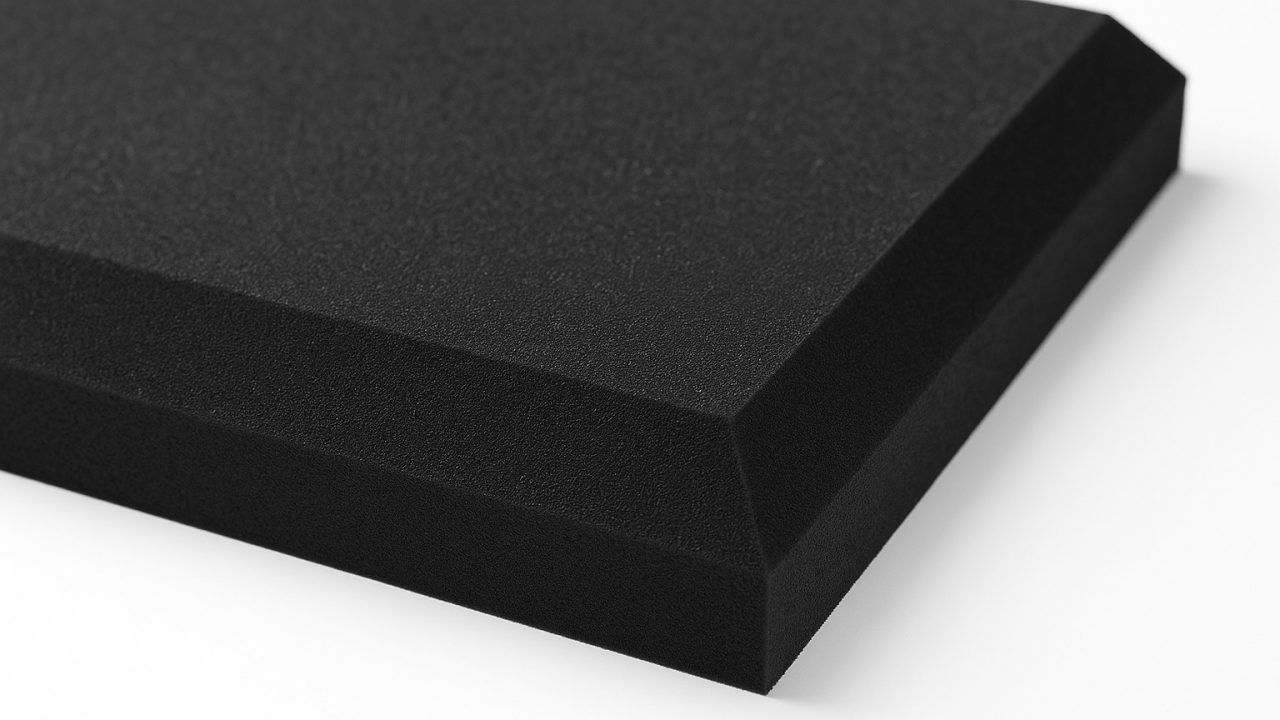

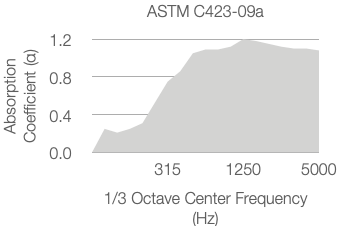

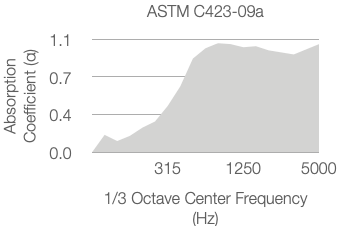

Flat 25

Cellyx™ Flat 25 panels use 25mm thick polyurethane foam to reduce echo and reverberation, offering a low-profile soundproofing solution with low VOC emissions.

Flat 50

Cellyx™ Flat 50 panels feature a 50mm thick low VOC polyurethane foam design, delivering high NRC acoustic ratings for sound absorption in professional interior environments.

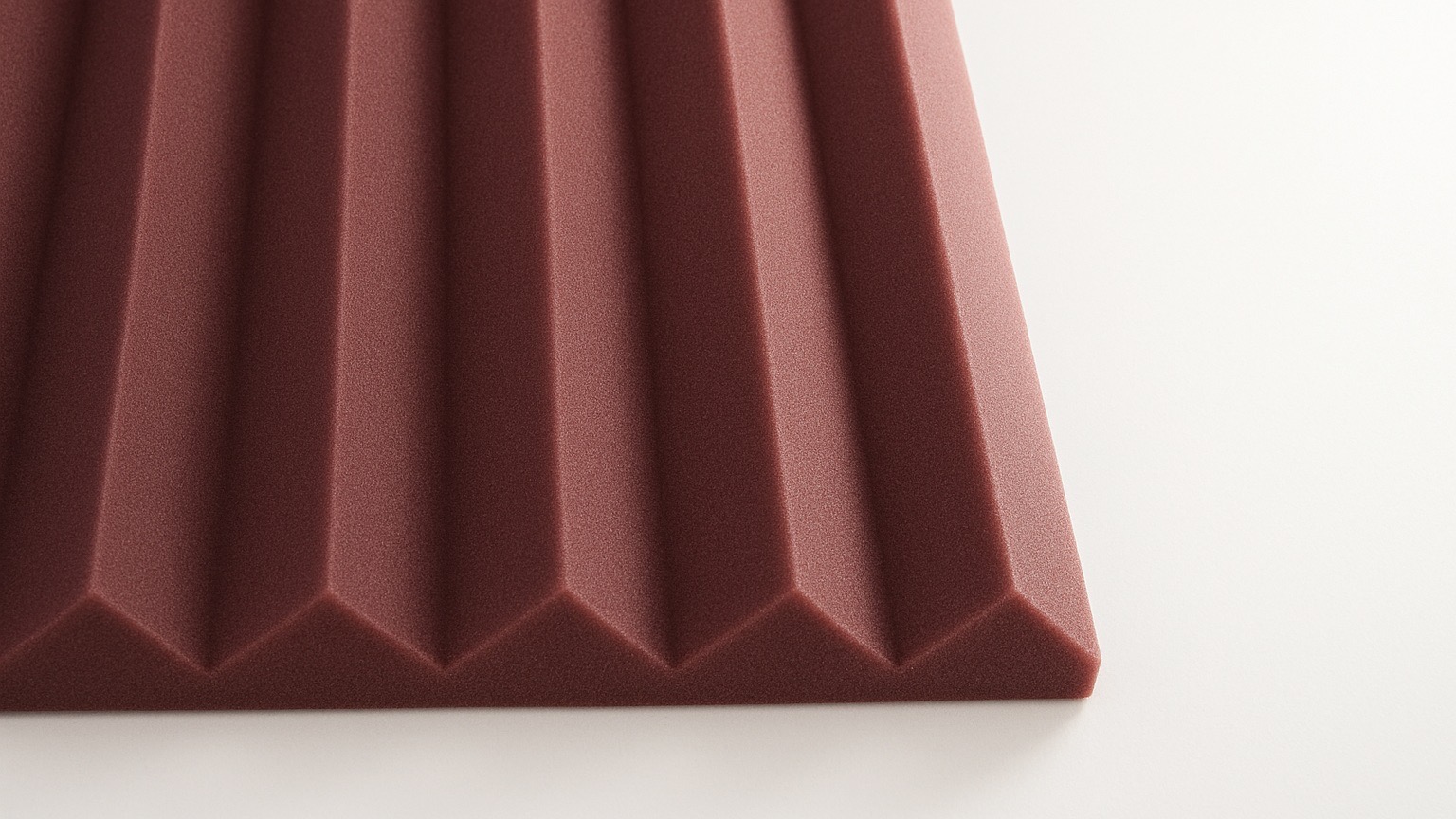

Pyramid

Cellyx™ Pyramid acoustic foam panels feature a sculpted 3D surface that increases contact with sound waves, reducing echoes and enhancing sound clarity.

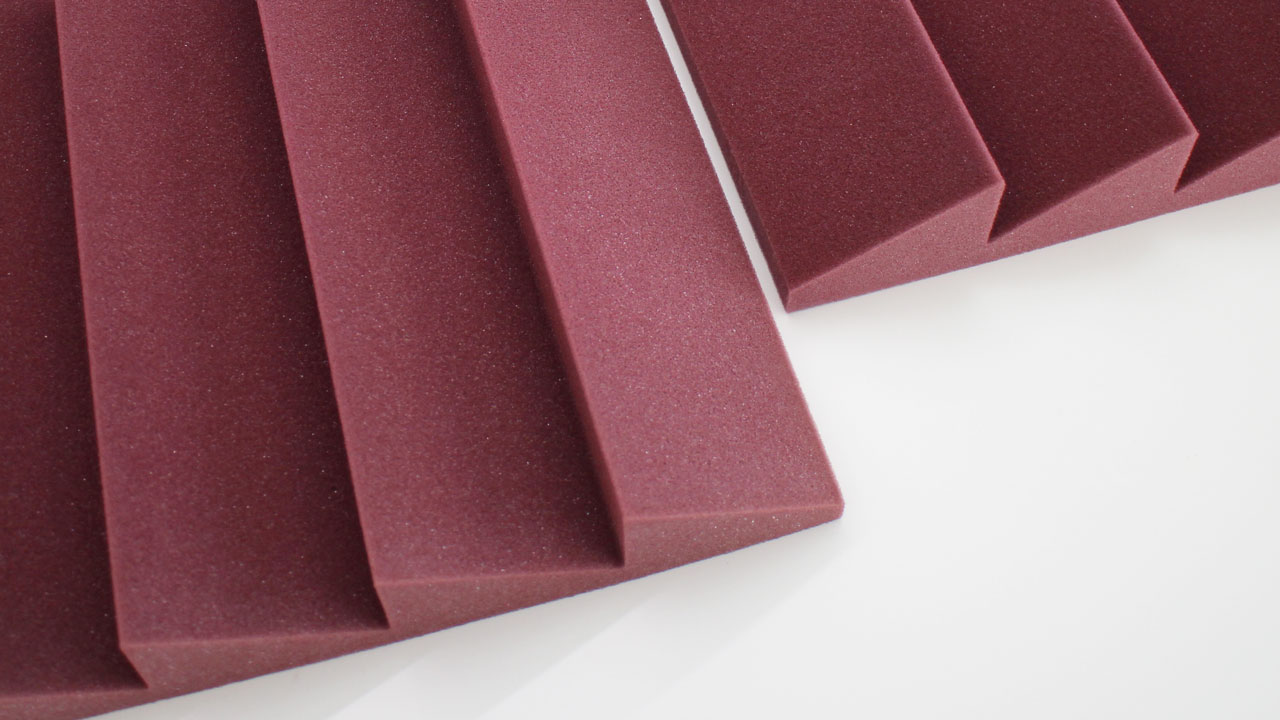

Louver 50a

Cellyx™ Louver 50a panels feature wide angled foam blades made from low VOC polyurethane, absorbing mid-to-high frequency sound in offices and studios.

Louver 50b

Cellyx™ Louver 50b panels use louvered foam fins to reduce reverberation, combining acoustic foam NRC performance with sustainable materials.

Wedge

Cellyx™ Wedge acoustic panels feature angled cuts in fire retardant foam, boosting mid-to-high frequency absorption.

Project Highlight

This residential project in Singapore aimed to reduce echo and improve acoustic comfort in a multi-purpose living and media room. Cellyx™ Flat panels were installed on upper walls to control reverberation and soften reflective surfaces. Their open-cell polyurethane structure absorbs mid-to-high frequency noise, creating a quieter and more comfortable home environment.

- Find the Designer

- Other Projects

How Does Cellyx™ Acoustic Foam Panel Work?

Cellyx™ Acoustic Foam Panels enhance sound absorption using precision-engineered open-cell polyurethane and high-density foam structures. These systems improve sound control, reduce echo, and increase overall comfort in any room. Designed with versatile profiles and modern aesthetics, they elevate interior spaces, resist moisture, and deliver practical benefits for customers. As an innovation-driven company, Cellyx™ develops foam panel solutions that balance acoustic performance, durability, and refined interior design.

Sound Absorption

In rooms with reflective surfaces and high ceilings, sound waves create echo and excessive reverberation that reduce speech clarity. Cellyx™ Acoustic Foam Panels are engineered to absorb sound at the source, helping to control noise levels, improve sound quality, and create a more comfortable acoustic environment in offices, auditoriums, and commercial spaces.

Designed for Architects

Effective acoustics should blend seamlessly with interior design. Cellyx™ Acoustic Foam Panels are available in a wide range of profiles, shapes, and surface textures to suit modern offices and public spaces. These foam panels integrate sound control without disrupting the visual identity of the room while enhancing overall comfort and acoustic performance.

Warranty Guaranteed

High-use environments require acoustic systems that last. Cellyx™ Acoustic Foam Panels are engineered with durable, fire-rated, and eco-conscious materials to deliver consistent sound absorption performance. Supported by reliable warranty protection, they offer long-term stability, acoustic benefits, and peace of mind for customers across various applications.

Frequently Asked Questions

Cellyx™ is a range of acoustic foam products made from fire-rated polyurethane or melamine foam. Instead of a rigid board like traditional acoustic panels, Cellyx™ uses open-cell foam that absorbs sound waves to reduce echoes and reverberation. It can be used as wall panels, ceiling tiles or suspended ceiling baffles for flexible and effective sound absorption.

Cellyx™ offers multiple profiles such as flat, wedge, pyramid and louvered foam. Standard panel sizes include 600 × 600 mm and 1200 × 1200 mm, with thicknesses from 25 mm up to 100 mm. Select profiles also come in 35 mm and 50 mm thickness options.

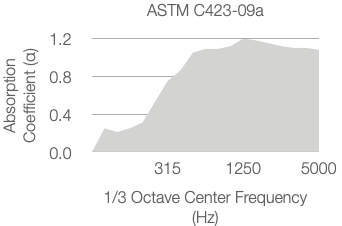

Cellyx™ acoustic foam delivers a Noise Reduction Coefficient (NRC) between 0.5 and 1.0, providing strong sound absorption across different frequencies. Shaped variants like wedge or pyramid foam increase surface area which helps trap and diffuse sound for better clarity and reduced reverberation.

Yes. Cellyx™ is fire-rated to Class A under ASTM E84-12a and is made with low-VOC materials. This makes it suitable for indoor acoustic treatment in homes, offices, studios and public spaces where safety and air quality matter.

Cellyx™ is commonly used in recording studios, auditoriums, offices, hospitality venues and other sound-sensitive environments. It can be installed as wall panels, placed as ceiling tiles or suspended as acoustic baffles and cylinders. Its lightweight construction makes installation easier than heavier acoustic boards.